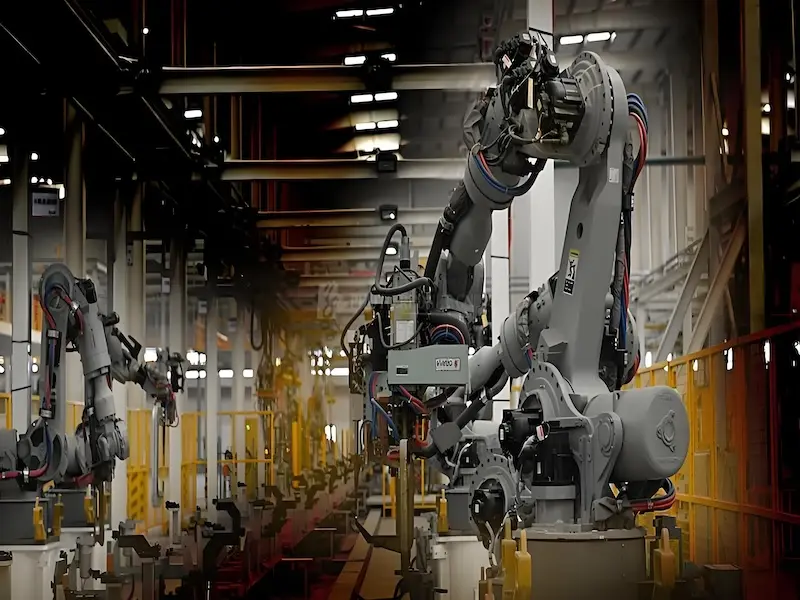

- It is a multi-jointed manipulator or multi-degree-of-freedom robot for the industrial field.

- The machine device that performs work automatically is a machine that achieves various functions by its own power and control ability.

- Industrial robots are used in a wide range of applications across various industries to automate tasks, improve efficiency, and enhance productivity.

Industrial robots are automated machines used in manufacturing. Typically, these versatile machines consist of at least one reprogrammable robotic arm or manipulator operating on three or more axes.

The widespread use of industrial robots in warehouses and factory assembly lines can be attributed to their ability to perform repetitive tasks quickly, with high precision, and without interruption.

Industrial robot definition

Industrial robots are robots that have been developed specifically to automate intensive production tasks, such as those required for constantly moving assembly lines. As large, heavy robots, they are placed in fixed locations within a factory and all other worker tasks and processes revolve around them.

Based on international standards, an industrial robot is defined as “a multifunctional, reprogrammable, automatically controlled manipulator that can be programmed in three or more axes and can be stationary in an area or moved for use in industrial automation applications”.

Industrial robots are usually not humanoid in form, although they are capable of replicating human movements and behaviours, but with the strength, precision, and speed of a machine.

According to Built In, Nadia Figueroa, a mechanical engineering and applied mechanics professor at the University of Pennsylvania believes that, due to the nature of the work they perform, “industrial robots must be strong, fast and accurate.”

That makes most industrial robots “quite large and dangerous for humans,” Figueroa, who also advises at the GRASP Lab, said. “They’re often inside cages or behind fences so that humans remain out of harm’s way.”

Also read: Automakers Magna to trial Sanctuary AI’s humanoid robots

Types of industrial robots

Industrial robots come in various types, each designed for specific tasks and applications. Here are some common types:

Articulated Robots: these robots have rotary joints resembling a human arm, typically with 6 degrees of freedom (DOF) or more, allowing for flexibility in movement. They are versatile and widely used for tasks like welding, material handling, assembly, and painting.

SCARA Robots (Selective Compliance Assembly Robot Arm): SCARA robots have two parallel rotary joints for horizontal movement and a linear joint for vertical movement. They excel in applications requiring fast and precise horizontal movements, such as assembly and pick-and-place tasks.

Delta Robots (Parallel Robots): delta robots feature a parallel linkage structure with three or more arms connected to a common base. They are known for their high-speed operation and are commonly used in tasks like packaging, sorting, and handling small parts in the food and electronics industries.

Cartesian/Gantry Robots: cartesian robots, also called gantry robots, move along three linear axes (X, Y, Z) on a Cartesian coordinate system. They are suitable for applications requiring precise linear movements, such as pick-and-place, dispensing, and CNC machining.

Collaborative Robots (Cobots): cobots are designed to work alongside humans in a shared workspace. They are equipped with safety features like force and torque sensors to detect human presence and avoid collisions. Cobots are used in various industries for tasks such as assembly, inspection, and packaging.

Mobile Robots: mobile robots are equipped with wheels or tracks for autonomous or semi-autonomous movement within a facility. They are used for tasks such as material transport, inventory management, and surveillance in warehouses, factories, and distribution centres.

These are just a few examples, and there are other specialised types of industrial robots designed for specific tasks and industries. The choice of robot type depends on factors such as the application requirements, workspace constraints, payload capacity, and desired level of automation.

Also read: AI robots with super vision power ‘groundbreaking’ warehouse

Advantages of industrial robots

There is no denying that industrial robots have revolutionised modern manufacturing. Here are some of the benefits of industrial robots.

Increased Productivity: industrial robots can work continuously and with high speed, leading to increased throughput and productivity in manufacturing processes.

Improved Quality: robots perform tasks with high precision and repeatability, resulting in consistent quality and reduced defects in production.

Enhanced Safety: by automating hazardous or repetitive tasks, robots can improve workplace safety by reducing the risk of accidents and injuries to human workers.

Cost Savings: while the initial investment in industrial robots can be significant, they can lead to long-term cost savings through increased efficiency, reduced labour costs, and minimised waste.

Flexibility: robots can be programmed and reprogrammed to perform various tasks, allowing manufacturers to adapt quickly to changes in production demands and product specifications.

24/7 Operation: industrial robots can work around the clock without fatigue, leading to continuous operation and reduced downtime in manufacturing facilities.

Consistency: robots perform tasks with consistent precision and accuracy, eliminating variability associated with human labour and ensuring uniformity in product quality.

Data Collection and Analysis: many industrial robots are equipped with sensors and data collection capabilities, allowing manufacturers to gather valuable insights into production processes and optimise performance.

Concerns about industrial robots

Although industrial robots offer numerous benefits to manufacturers, they also have some concerns.

Job Displacement: one of the primary concerns is that the automation of tasks previously performed by humans may lead to job displacement and unemployment, particularly for workers in industries heavily affected by automation.

Skill Shift: the rise of industrial robots may require workers to acquire new skills to operate, programme, and maintain these machines, leading to challenges in workforce transition and retraining.

Safety Risks: despite safety features, industrial robots can still pose safety risks to human workers, especially during interactions in shared workspaces. Accidents can occur due to mechanical failures, programming errors, or improper maintenance.

Ethical Considerations: there are ethical considerations surrounding the use of industrial robots, particularly in cases where automation leads to job loss or exacerbates socio-economic inequalities. Additionally, concerns about the impact of automation on human dignity and autonomy have been raised.

Cybersecurity Vulnerabilities: industrial robots are increasingly connected to networks and systems, which raises concerns about cybersecurity vulnerabilities. Hackers could exploit these vulnerabilities to gain unauthorised access to robots, leading to safety risks or disruptions in production.

Overreliance on Automation: overreliance on industrial robots for production processes could make manufacturers vulnerable to disruptions caused by technical failures, supply chain interruptions, or cyberattacks. It may also reduce the agility and adaptability of manufacturing operations.

Environmental Impact: while industrial robots can contribute to efficiency and resource optimisation, concerns exist about their environmental impact, particularly regarding energy consumption, waste generation, and the use of materials in manufacturing processes.

Socio-economic Impacts: automation driven by industrial robots may exacerbate socio-economic inequalities by widening the gap between skilled and unskilled workers and concentrating wealth and power in the hands of corporations and technology developers.

Addressing these concerns requires careful consideration of the social, economic, ethical, and environmental implications of industrial robot adoption. It also entails proactive measures to mitigate risks, ensure worker safety and well-being, and promote equitable and sustainable automation practices.

How are industrial robots used in daily life?

Today, there are more than 3.4 million industrial robots in the world, and the global ratio of robots to humans in manufacturing is 1 to 71. And, according to a survey by McKinsey, industrial companies plan to invest a quarter of their capital in robotics. Robotics over the next five years – the market is expected to reach $43 billion in revenue by 2027.

Industrial robots are used in a wide range of applications across various industries to automate tasks, improve efficiency, and enhance productivity. Here are some common ways industrial robots are used:

Manufacturing and Assembly: industrial robots are extensively used in manufacturing processes to assemble components, weld parts together, handle materials, and perform other production tasks. They can work with high precision and repeatability, leading to improved quality and consistency in assembly operations.

Welding: robots are widely used for welding applications in industries such as automotive, aerospace, and metal fabrication. They can perform various welding techniques, including arc welding, spot welding, and laser welding, with accuracy and speed, resulting in consistent weld quality and reduced cycle times.

Material Handling and Packaging: industrial robots are employed for material handling tasks such as picking, placing, palletizing, and packaging goods in warehouses, distribution centres, and manufacturing facilities. They can handle heavy loads and operate continuously, leading to increased throughput and efficiency in logistics operations.

Painting and Coating: robots equipped with paint sprayers are used for automated painting and coating applications in industries such as automotive manufacturing, aerospace, and consumer electronics. They can apply paint or coatings evenly and precisely onto surfaces, reducing waste and improving finish quality.

Inspection and Quality Control: robots equipped with sensors and cameras are used for inspecting products, components, or facilities for defects, quality control, or safety purposes. They can detect flaws, measure dimensions, and perform quality checks with high accuracy and consistency, ensuring product quality and compliance with standards.

Machine Tending: robots are employed for loading and unloading parts from machine tools such as CNC (Computer Numerical Control) machines, lathes, and milling machines. They can operate continuously and autonomously, reducing downtime and increasing machine utilization in manufacturing processes.

Testing and Measurement: robots are used for testing and measuring components or products in industries such as electronics, automotive, and aerospace. They can perform tasks such as electrical testing, dimensional inspection, and material analysis with precision and efficiency, ensuring product reliability and performance.

Collaborative Work: collaborative robots (cobots) are designed to work alongside humans in a shared workspace. They are used for tasks such as assembly, inspection, and packaging, where close collaboration between humans and robots is required. Cobots are equipped with safety features to ensure safe interaction with human workers.

Industrial robots play a crucial role in automating a wide range of tasks in manufacturing and industrial settings, bringing a new world for the future.