- Tesla is pioneering a new “unboxed” assembly method, aiming to streamline production and cut costs.

- CEO Elon Musk suggests this approach will revolutionize manufacturing and lead to a more affordable $25,000 car, expected by late 2024 or early 2025.

- Initial reports indicate potential cost reduction by 50% and 40% less factory space, but specific details and the first deployment location remain undisclosed.

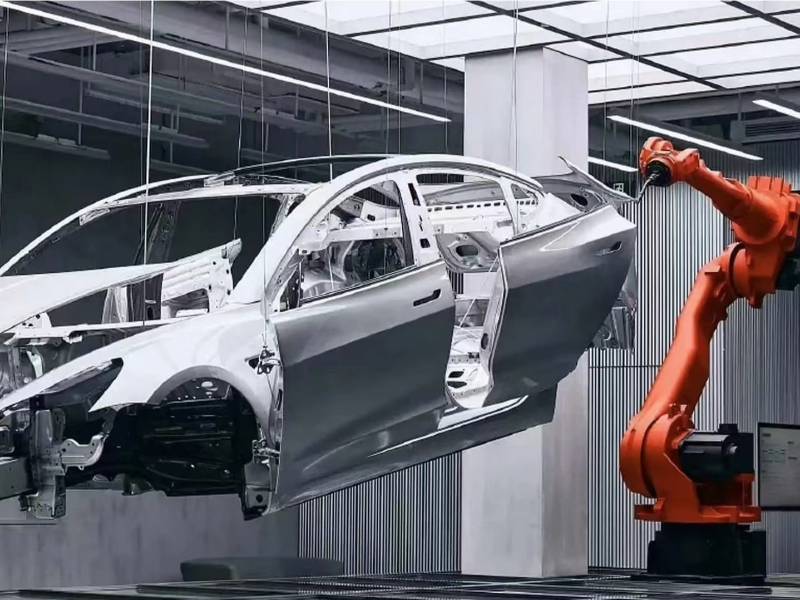

Tesla has long been known for disrupting traditions, and its integrated casting technology is a prime example. Now, according to insideevs, Tesla plans to implement a new car assembly method, believing it will help reduce costs and simplify assembly processes.

This approach, dubbed “unboxed” assembly technology, will discard traditional assembly line operations, no longer requiring car bodies to sequentially pass through various stations for part assembly. Tesla’s “unboxed” approach involves simultaneously assembling different parts of the car in different areas of the factory, and then assembling several large subcomponents together at the end.

Also read: Tesla raises prices in China and shrugs off price war

Also read: China’s Xiaomi joins the EV race with ‘dream car’ to take on Tesla

It can reduce factory space requirements by about 40%

It is reported that this approach can halve production costs and reduce factory space requirements by about 40% compared to traditional car factories if true, it will significantly lower Tesla’s manufacturing costs, thereby reducing the overall vehicle price.

Tesla CEO Elon Musk has hinted at adopting this new production method several times, but has not disclosed specific details. So far, he has only mentioned that the new technology for producing the upcoming $25,000 car (approximately RMB 181,000 at current exchange rates) will be “revolutionary” and “much more advanced than any car manufacturing system in the world.”

It will start production (or at least be announced) by the end of 2024 or early 2025

This affordable Tesla model is expected to start production (or at least be announced) by the end of 2024 or early 2025. Musk also confirmed that the project is “very close to completion,” but did not reveal more details.

Automotive News website quotes Mathew Vachaparampil, CEO of engineering and automotive benchmark testing company Caresoft, as saying that Tesla first validated the feasibility of the “unboxed” assembly method through digital simulation. He did not disclose the results of the simulation test, but he did confirm that this innovative car manufacturing method will significantly reduce Tesla’s manufacturing costs.

It is currently unclear where Tesla will first adopt this “unboxed” method, but it may be related to its upcoming economy models. Considering that Tesla is currently building or expanding multiple factories, this technology may be first deployed in China, Berlin, or even Mexico.