- SpaceX’s Starlink, led by Elon Musk, and Trump’s ‘America First’ policies could reshape U.S. IT infrastructure by driving domestic production of critical technologies.

- Experts caution that reversing globalized supply chains requires immense resources and time, raising questions about the feasibility of such ambitious goals.

Elon Musk’s ambitions with SpaceX’s satellite network, Starlink, extend far beyond providing global internet access. When combined with former President Donald Trump’s push for domestic manufacturing under his ‘America First’ policies, a unique opportunity arises: the potential to reshape U.S. IT infrastructure by bringing more production within national borders. Thus, SpaceX’s domestic satellite factories and the strategic focus on onshoring production could not only catalyze a renaissance in IT supply chains but also influence global competition and data sovereignty. However, while this vision sounds promising, the reality of reversing decades of globalized supply chains and production networks is far more complex than it may seem.

Musk’s satellite impact on U.S. IT infrastructure: A globalized paradox

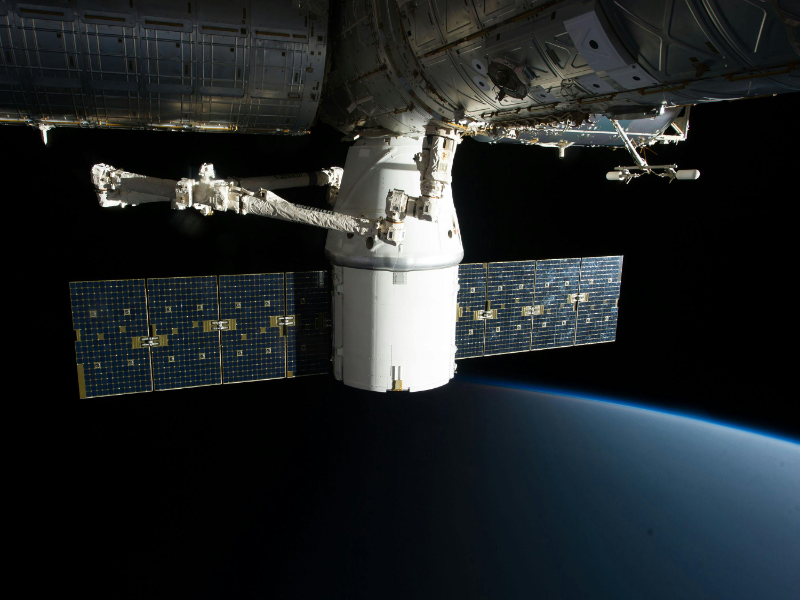

SpaceX’s Starlink initiative has captured global attention for its ambitious plan to revolutionize internet access. By launching thousands of low-earth orbit satellites, the company aims to provide connectivity in remote and underserved regions.

Also read: SpaceX and ESA discuss solutions as space junk hits critical mass

A key feature of this strategy is SpaceX’s decision to produce satellites within the U.S., signaling a commitment to domestic manufacturing. The significance of this decision goes beyond the satellites themselves, touching on the broader implications for U.S. IT infrastructure and national security. But while the optics of American-made satellites are appealing, the reality of reshoring high-tech production is more complex.

Sid Rao, CEO of Positron Networks, critically examines the narrative of American manufacturing supremacy in aerospace. “When looking at this question, it is crucial to decouple design and assembly from the part production and the underlying supply chain. While an economic agenda that favors American production would increase assembly and design investments in the United States, the underlying aerospace supply chain has become aggressively globalized, and it would take decades to reverse this momentum,” Rao states. His insight reveals the paradox at the heart of the current push for domestic production: while assembly and design may return to U.S. shores, much of the crucial supply chain remains globally distributed, from parts sourcing to component manufacturing.

SpaceX, as a leader in satellite production, exemplifies this challenge. While the company does produce its satellites in the U.S., Rao stresses the importance of considering the global supply chain that supports these operations. “Since 2010, the aerospace industry has extensively leveraged commercial off-the-shelf (COTS) equipment, with less specialized components and software, to scale production and lower design and build costs,” Rao explains. This shift toward global sourcing has made the industry more efficient but has also reduced the feasibility of fully domestic projects. The transition back to highly specialized, locally sourced components reminiscent of NASA and DoD’s past practices, he argues, would be prohibitively expensive and inefficient.

The broader economic and strategic implications

The Trump administration’s push for reshoring critical industries, including aerospace, highlights the tension between national security concerns and the reality of a globalized supply chain. The proposed tariffs and incentives aimed at encouraging U.S.-based manufacturing seek to address this imbalance, but experts like Rao caution against oversimplifying the benefits. “It is incredibly capital-intensive to vertically integrate all the subcontractors involved in an aerospace project, with limited operational benefits,” he says. Using the example of the F-35, a flagship American defense project, Rao notes that despite its designation as an American initiative, less than 10% of its production manhours occur within the U.S. “If it wasn’t for this globalized approach, the F-35 may not have even been economically feasible,” he adds. This points to a deeper issue: reshoring, while appealing, may not be the panacea that many assume it to be.

“It is incredibly capital-intensive to vertically integrate all the subcontractors involved in an aerospace project, with limited operational benefits.”

Sid Rao, CEO of Positron Networks

Rao further explores the broader implications of relying on globalized supply chains for high-tech infrastructure. The software and artificial intelligence (AI) models used in launch vehicles, for instance, are global projects in their own right. “Sophisticated computer vision and signal processing models are necessary for developing reusable launch control systems. These models are built using ASICs and GPUs that are globally designed, developed, and sourced,” Rao explains. Even with the U.S. government’s efforts to bolster domestic chip manufacturing through the CHIPS Act, the nature of these projects remains fundamentally international. For example, chips used in computer vision models for space applications are designed by companies like Annapurna Labs in Israel and manufactured in Asia. This interconnectedness of the global supply chain underscores how difficult it would be to consolidate these technologies solely within the U.S.

Is SpaceX an outlier or is the industry heading toward a new norm?

Given the constraints, one must ask whether SpaceX is a true outlier in terms of its domestic manufacturing efforts or if it is simply emblematic of the larger trends in aerospace. While Musk’s focus on U.S.-based satellite production may set an example for other companies, it is crucial to recognize the limits of this model in a globalized economy.

Rao challenges the assumption that tariffs or other protectionist measures can bring the aerospace industry back to a purely domestic framework. “Even with tariffs potentially encouraging more production in the United States, the tradeoff still favors globalization over building and maintaining domestic foundries, software development facilities, and chip lines,” he concludes.

Also read: SpaceX makes history by successfully catching returning starship booster with giant ‘chopsticks’

Also read: Musk’s SpaceX set for $250B valuation with tender offer

Moreover, while SpaceX protects Starlink’s design principles and supply chain as a domestic trade secret, the question remains on whether the very feasibility of SpaceX’s business model itself rely on globalization. “In fact, I wonder if SpaceX could even exist without globalization!” Rao’s rhetorical question underscores the essential role that international collaboration and global supply chains play in enabling high-tech companies to thrive. The question remains: can a truly domestic IT infrastructure be built in today’s interconnected world?

Rethinking the future of U.S. IT infrastructure

While SpaceX’s commitment to U.S.-based satellite production is aligned with Trump’s ‘America First’ manufacturing vision, the complexities of globalized supply chains challenge the feasibility of such policies. Analysis reveal that reshoring production would require decades of retooling, immense capital investments, and uncertain benefits. Yet, Trump’s 2024 re-election campaign is reigniting these ambitions, promoting a return to domestic manufacturing and emphasizing the need for U.S. control over critical IT infrastructure.

However, as experts point out, this vision risks oversimplifying the reality of modern aerospace and IT supply chains, which are deeply international in scope. Even if Trump’s policies encourage more onshore assembly and design, the underlying dependence on global suppliers, from AI models to semiconductor production, cannot be easily undone. This tension highlights the challenge of reconciling political promises with economic and technological realities.